近期,我院研究生宋子龙(一作),教师王蛟(通讯)等的研究成果“Design of multi-pipe latent heat storage device based on bionic topological optimization”在《Applied Thermal Engineering》(IF=6.1)上发表。

论文简介如下:

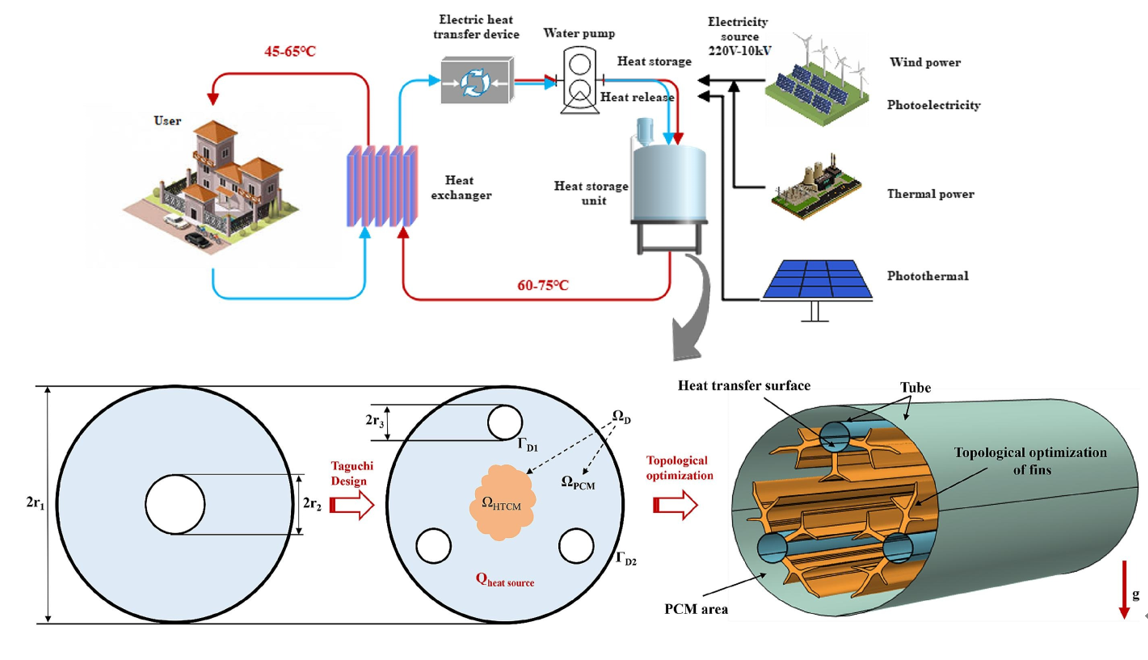

潜热热能储存系统具有高效热能储存的巨大潜力,但其发展受到储存材料低热导率的限制。本文中提出了一种基于三根均匀分布内管的仿生拓扑结构,并将其应用于卧式潜热储存装置中。首先,利用田口设计方法确定了内管的最佳布置,实现了0.7的偏心率和0°的管旋转角。基于这种布置,设计了拓扑优化的翅片,并建立了翅片体积分数的最佳范围,同时考虑了能量存储密度、热量存储和释放速率以及经济成本。随后,考虑了自然对流对相变传热的影响,并比较了四种不同的蓄热模型,包括拓扑优化翅片模型,分析了它们在熔化和凝固过程中的传热和流动特性。结果表明,通过田口设计优化的三管布置使单循环蓄放热时间缩短了53.49%,而热循环速率提高了2.22倍。此外,与传统翅片结构相比,将拓扑结构结合到三管布置中增加了额外的2.08倍的热循环速率,而相变材料在熔化和凝固期间的温度分布不均匀性分别降低了65.32%和85.26%。此外,本文观察到拓扑优化的鳍结构表现出类似于天然形式中发现的分形维数,如叶脉和雪花。该研究为潜热储存系统的性能优化提供了一种新的途径。

Latent heat thermal energy storage systems hold great potential for efficient thermal energy storage, but their development is limited by the low thermal conductivity of storage materials. In this study, we propose a bionic topology structure based on three evenly distributed inner tubes for application in a horizontal latent heat storage device. Utilizing the Taguchi design method, we first identified the optimal arrangement of the inner tubes, achieving an eccentricity of 0.7 and a tube rotation angle of 0°. Building on this arrangement, we designed topology-optimized fins and established the optimal range for the fin volume fraction, taking into account energy storage density, heat storage and release rates, and economic costs. Subsequently, we considered the influence of natural convection on phase change heat transfer and compared four different heat storage models, including those with topology-optimized fins, analyzing their heat transfer and flow characteristics during the melting and solidification processes. The findings indicated that the three-tube arrangement optimized through the Taguchi design reduced the single-cycle heat storage and release time by 53.49% while increasing the heat cycle rate by 2.22 times. Furthermore, incorporating a topology structure into the three-tube arrangement enhanced the heat cycle rate by an additional 2.08 times compared to traditional fin structures, while the temperature distribution non-uniformity of the phase change material during melting and solidification decreased by 65.32% and 85.26%, respectively. Additionally, we observed that the topology-optimized fin structure exhibits fractal dimensions akin to those found in natural forms, such as leaf veins and snowflakes. This study offers a novel approach for the performance optimization of latent heat storage systems.

Optimization design of the phase change thermal storage unit in the electric thermal storage process.

全文下载:https://doi.org/10.1016/j.applthermaleng.2024.125402