近期,我院教师孙慧(一作,通讯)、硕士生胡康等的综述“Review of fault modes and failure diagnosis methods for magnetic-driving pump”在中科院二区期刊《Structural Health Monitoring》(IF=5.8)上发表。

论文简介如下:

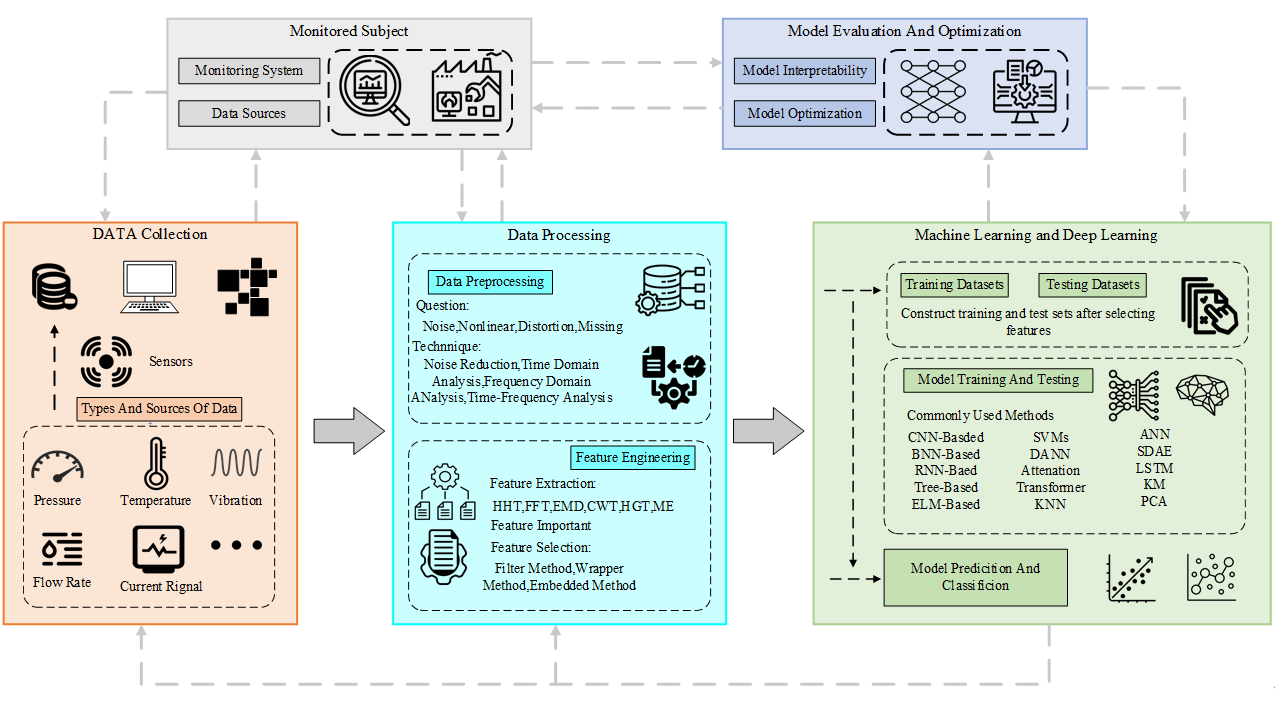

磁力驱动泵利用磁感应传递扭矩,具有较为优越的密封性,能够更安全、高效地处理有害或珍贵流体,因此广泛应用于工业过程中。尽管磁力泵的可靠性高,但仍存在温度升高、润滑不足和污染等导致故障风险的潜在问题。本文主要探讨了磁驱动泵的故障模式、故障原因及其影响,并提供了先进的传感器及智能诊断方法在预测和防止故障中的应用,以确保稳定的运行并减少停机时间。首先介绍了磁驱动泵的结构和工作原理,特别是其无密封设计如何有效减少了环境污染的风险,保护了易燃、易爆、或有腐蚀性的介质。文中指出,与传统泵相比,磁驱动泵的生命周期维护成本降低了20%至30%。接着对磁力泵的各种故障模式进行分类,并探讨了各种故障的原因以及可能造成的影响。并且磁力泵的故障模式之间也不是相互独立的,有些故障之间存在着连锁反应形成复合故障。然后本文对多种常见的故障诊断技术进行分析总结包括模型驱动、数据驱动和模型-数据的混合驱动方法。文中对三种方法的优点、缺点和应用场景进行了深入的分析。最后总结了磁力泵故障诊断的未来研究方向,强调还需要更多的研究来完善和改进磁力泵故障诊断的准确性和有效性。同时在智能制造与工业4.0的背景下,集成智能传感器和人工智能算法的智能故障诊断系统将是磁驱动泵故障诊断技术发展的关键。这将不仅提高故障诊断的速度和准确性,还能降低维护成本,增强系统的可靠性。

Magnetic drive pumps are widely used in industrial processes because they use magnetic induction to transmit torque, have superior sealing and are able to handle hazardous or valuable fluids more safely and efficiently. Despite the high reliability of magnetic drive pumps, there are potential problems such as elevated temperatures, inadequate lubrication and contamination that contribute to the risk of failure. This paper focuses on the failure modes, causes and effects of magnetic drive pumps and presents the use of advanced sensors and intelligent diagnostics to predict and prevent failures to ensure stable operation and reduce downtime. It begins by describing the design and operation of magnetic drive pumps, in particular how their seal-less design effectively reduces the risk of environmental contamination and protects flammable, explosive or corrosive media. The paper points out that the life cycle maintenance costs of magnetic drive pumps are reduced by 20% to 30% compared to conventional pumps.Then, the various failure modes of magnetic pumps are categorised and the causes of various failures and their possible effects are discussed. And the failure modes of magnetic pumps are not independent of each other, and there is a chain reaction between some failures to form a composite failure. This paper then analyses and summarises a variety of common fault diagnosis techniques, including model-driven, data-driven and model-data hybrid drive methods. The advantages, disadvantages and application scenarios of the three methods are analysed in detail. Finally, the future research direction of magnetic pump fault diagnosis is summarised, emphasising that more research is needed to refine and improve the accuracy and effectiveness of magnetic pump fault diagnosis. Meanwhile, in the context of intelligent manufacturing and Industry 4.0, an intelligent fault diagnosis system that integrates intelligent sensors and artificial intelligence algorithms will be the key to the development of magnetic drive pump fault diagnosis technology. This will not only improve the speed and accuracy of fault diagnosis, but also reduce maintenance costs and improve system reliability.

Figure A unified ML framework for magnetic pump fault diagnosis.