近期,我院教师冯国增(通讯),研究生夏昱翔等的研究成果

“Research and optimization of new wavy fin geometry parameters in

positive temperature coefficient heaters for electric vehicles” 在《Applied Thermal Engineering》(IF=6.4)上发表。

论文简介如下:

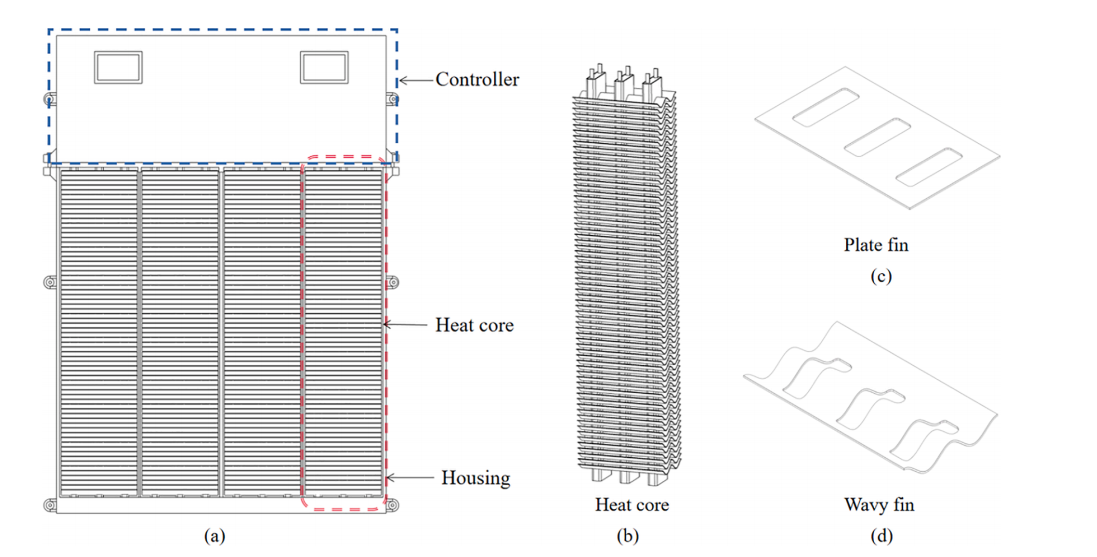

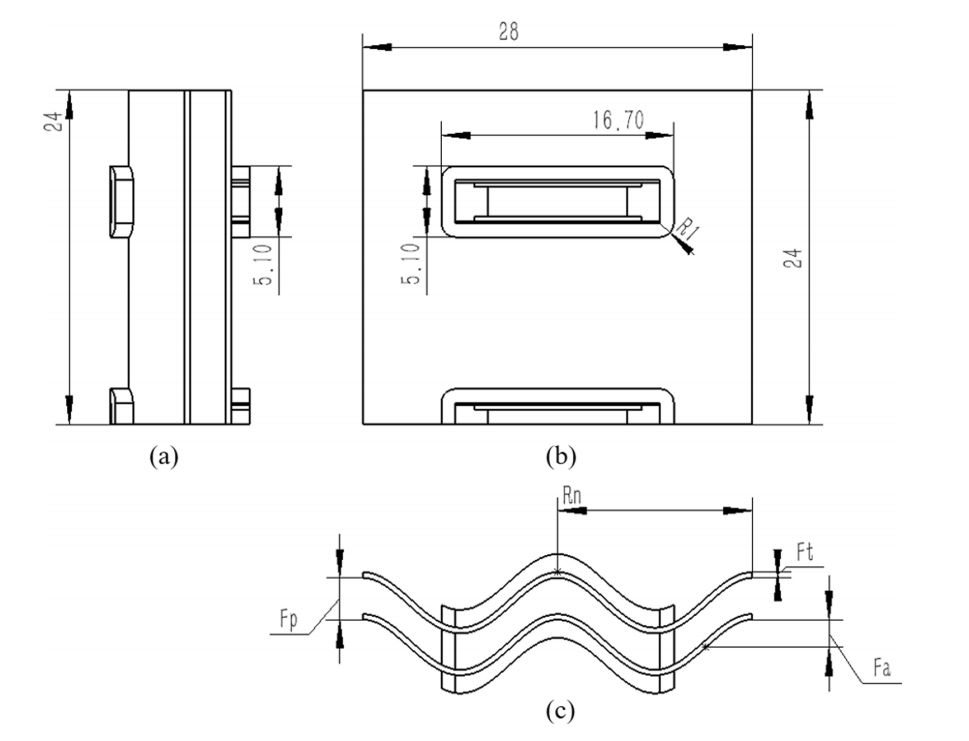

The positive temperature coefficient (PTC) heater is an automotive heating device widely used in electric vehicles to ensure the conversion efficiency of the battery in winter, but the heater consumes a large amount of battery capacity. Therefore, it is necessary to improve the performance of PTC heaters to meet the maximum mileage of electric vehicles in winter. We propose to replace plate fin heating with wavy fins and develop PTC heaters with 7 kW class and higher heating performance. In the flow rate range of 100–500 kg/h, this study investigates the effects of four parameters, including fin pitch (Fp), fin amplitude (Fa), fin thickness (Ft) and ripple number (Rn) on the heat transfer performance and resistance performance of the heater by numerical simulation. The area goodness factor is chosen as the performance evaluation criterion for heat transfer and flow. Based on the multi-response Taguchi design method, the influence factors are Fp, Fa, Ft and Rn, with four levels of each factor. Heating capacity, AGF and pressure drop is used as three response, and the comprehensive weighted score is taken as the overall performance criterion. The results of the range analysis and analysis of variance (ANOVA) using Minitab software show that reducing Fp and choosing a smaller Rn can improve the overall performance, the best overall performance when Ft = 0.3 mm, Fa is a secondary factor and it reflects the volatility. The optimal combination of Fp = 2 mm, Fa = 0.8 mm, Ft = 0.3 mm and Rn = 2 was obtained by discussing the design parameters. The new wavy fin heater has a heating performance of 7.19 kW and a pressure drop of 18.3 Pa. At the standard flow rate, the wavy fin heater has 16.91 % higher heating capacity, 7.95 % higher pressure drop and 33.40 % higher AGF than the plate fin heater. The comparison of results shows that the numerical simulation and analysis method based on Taguchi’s design proposed in this paper can achieve the optimal design of PTC heaters, this method provides a reference for the performance prediction and parameter design of early products.