近期,我院博士研究生邱浩(第一作者)、教师苏超(通讯作者)等的研究成果“Constructing an expeditious and durable composite as an air electrode of solid oxide cells through synergistic phase transformation and phase segregation engineering”在中科院一区、材料科学TOP期刊《Composites Part B: Engineering》(IF=12.7)上发表

论文简介如下:

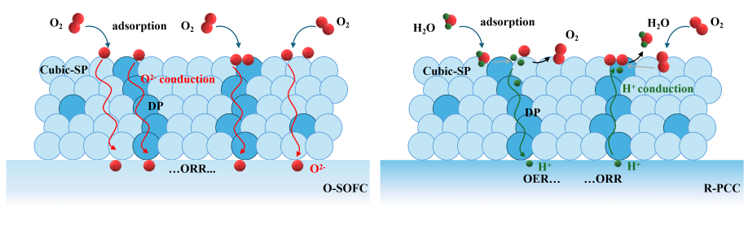

固体氧化物电池(SOC)面临的主要问题是空气电极在中低温下(<650°C)的电催化活性不足。本论文报道了一种具有高电化学活性和稳定性的铁基复合材料,并用作SOC的空气电极。该复合材料由立方的单钙钛矿(SP)主相和富含氧空位的双钙钛矿(DP)次要相组成。实验表明,五价的元素掺杂可以有效地抑制原始四方的SP的形成,并诱导形成具有高对称性的立方的SP。此外,原位形成的DP将与SP引起协同作用,进一步提高材料电催化活性。以该复合材料为空气电极,氧离子导电的固体氧化物燃料电池(O-SOFC)在600 °C时,峰值功率密度(Pmax)可以达到1259 mW cm−2,大约是以SrFeO3−δ电极的2.1倍(595 mW cm−2)。当该复合材料作为可逆质子陶瓷电池(R-PCC)空气电极时,电池在650 °C时的Pmax高达844 mW cm−2,电解电流密度为-957 mA cm−2(1.3 V)。此外,该电池在燃料电池模式下可以稳定运行500小时,在循环模式下(燃料电池和电解电池模式之间交替)可以稳定运行210小时。

The sluggish catalytic activity of iron-rich perovskite-based air electrodes at low temperatures (< 650 °C) is a common problem faced by solid oxide cells (SOCs). Herein, an expeditiousand durable iron-rich, multifunctional, composite material is reported as an outstanding air electrode for SOCs. Such a composite consists of a dominant cubic single perovskite (SP) phase,and a minor oxygen vacancy-rich double perovskite (DP) phase. The incorporation of pentavalent Ta and Nb effectively inhibits the formation of tetragonal SP and induces phase transformation to a cubic SP with high symmetry, while the in-situseparatedDP phase synergistically boosts the performance of oxygen activation. Such multiple benefits result in the generation of an oxygen-ion conductor-based solid oxide fuel cell (O-SOFC) with the developed composite electrode that yields a superb maximum power density (Pmax) of 1259 mW cm−2 at 600 °C, ~ 2.1 times that of an O-SOFC with SrFeO3−δ parent electrode (595 mW cm−2). Areversible protonic ceramic cell (R-PCC) with such composite air electrode delivers a remarkable electrochemical performance,e.g., a Pmax of 844 mW cm−2 and an electrolysis current density of −957 mA cm−2 @ 1.3 V at 650 °C. More attractively, the resulting cell exhibits an outstanding operating endurance of 500 hours in fuel cell mode and 210 hours in cycle mode (i.e., alternating between fuel cell and electrolysis cell modes).

Possible reaction mechanisms of this composite air electrode for O-SOFC and R-PCC.